Tutorial- Attaching pieces of leather- rivetting

One of the strongest and easiest ways to attach smaller pieces of leather together is through rivetting. Now, there are differed types of rivets, in differed materials from regular steel,stainless steel, and copper. For leather working there are 2 predominately used types of rivets:

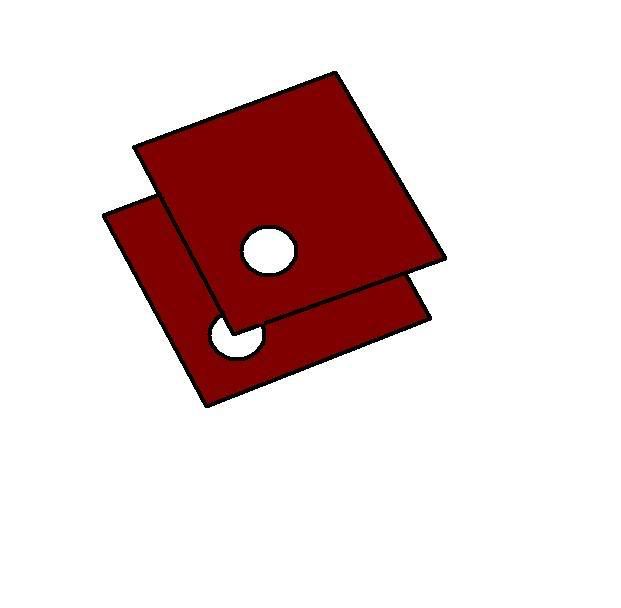

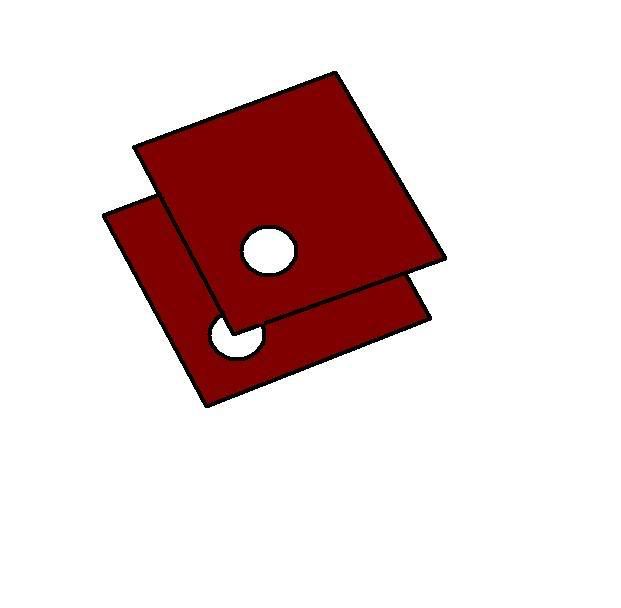

solid copper rivets with washers called burs:

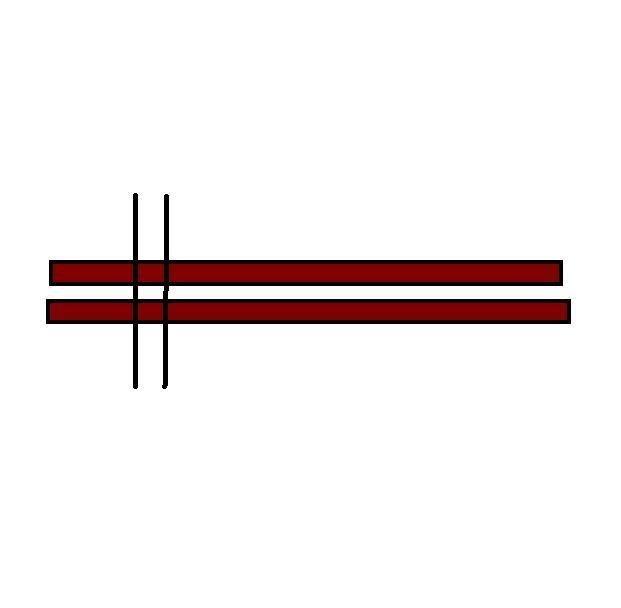

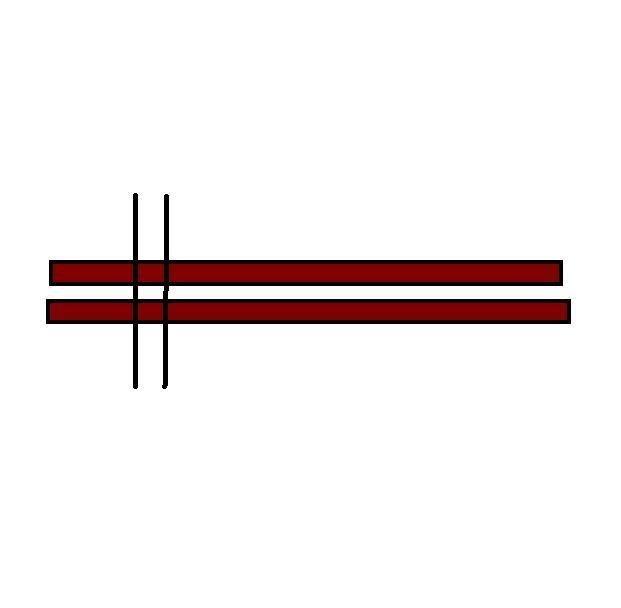

and hollow lightweight quich rivets, made mostly from thin steel, and colored brass, blackened, or nickel silver:

The quick rivets are used predominately in areas not directly in contact with combat,ie: fashion pieces or occasional strapping. For areas with heavy stress is implied, like areas struck in combat, the solid copper rivets are recommended for their strength.

To attach the quick rivets is very easy and fast, albeit not very strong for the piece. Steps are

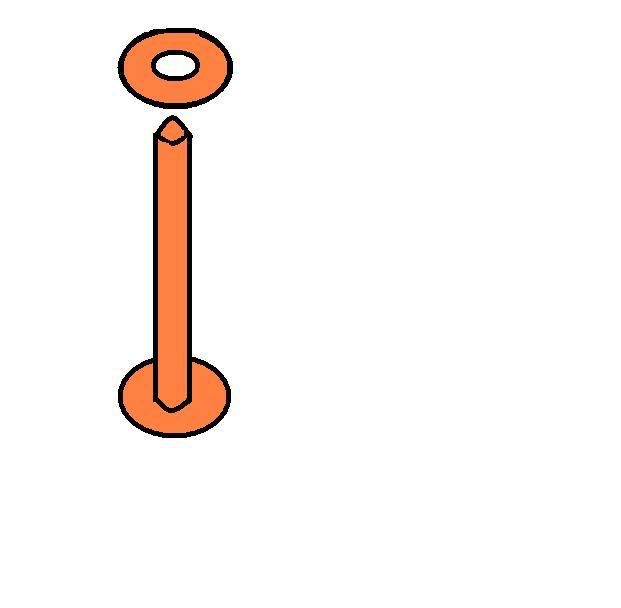

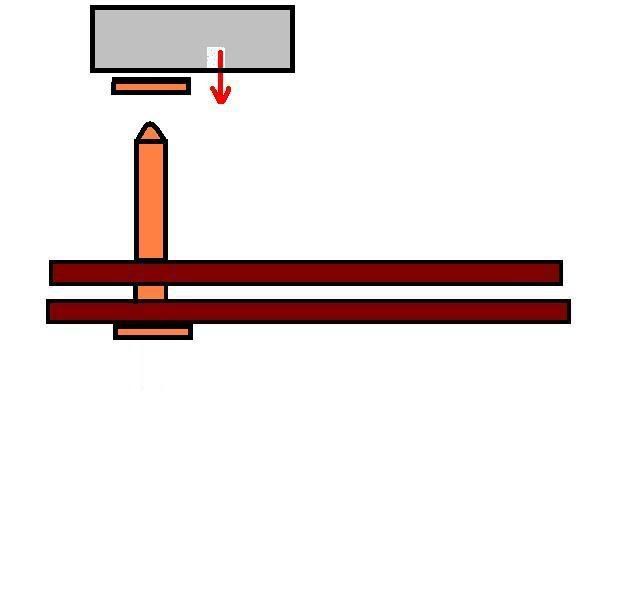

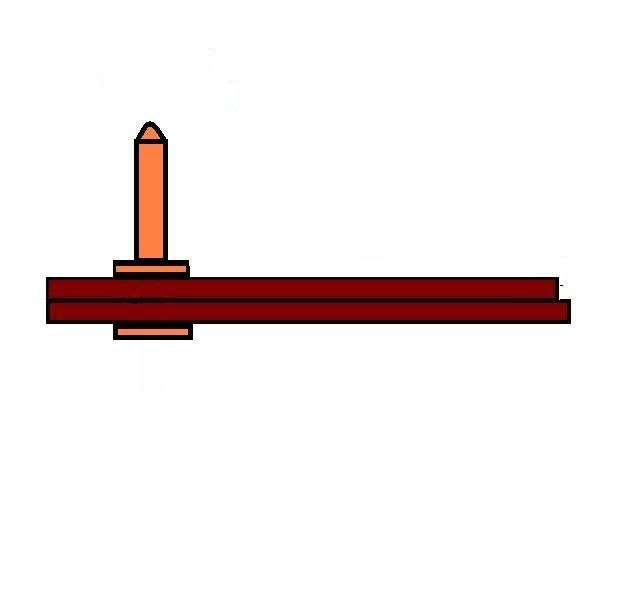

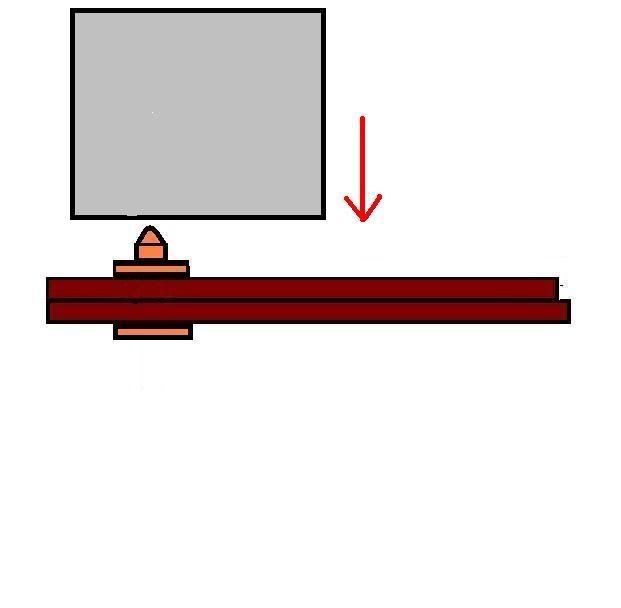

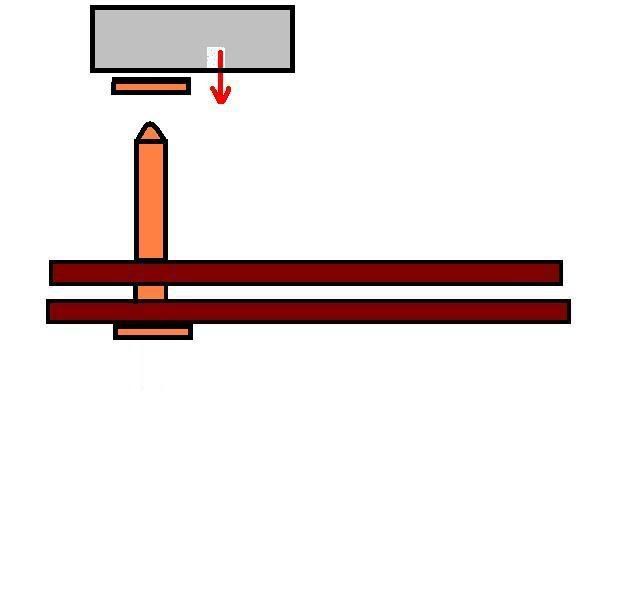

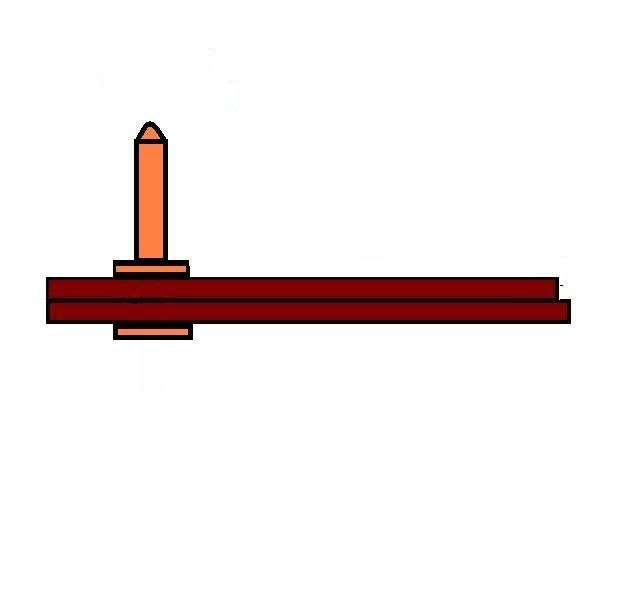

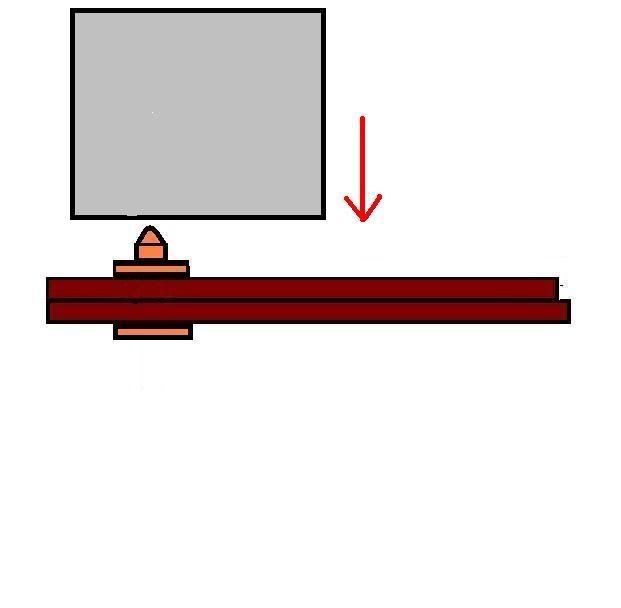

1. Feed the long neck end through the bottom of your two pieces of leather.

2. Cover long neck end with cap

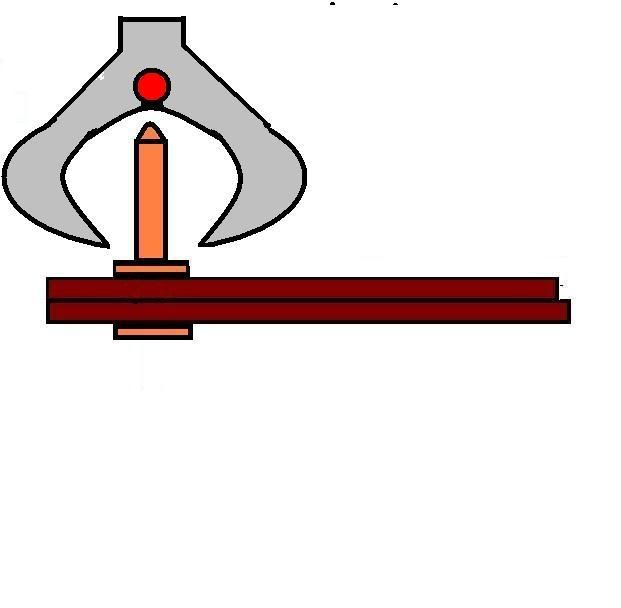

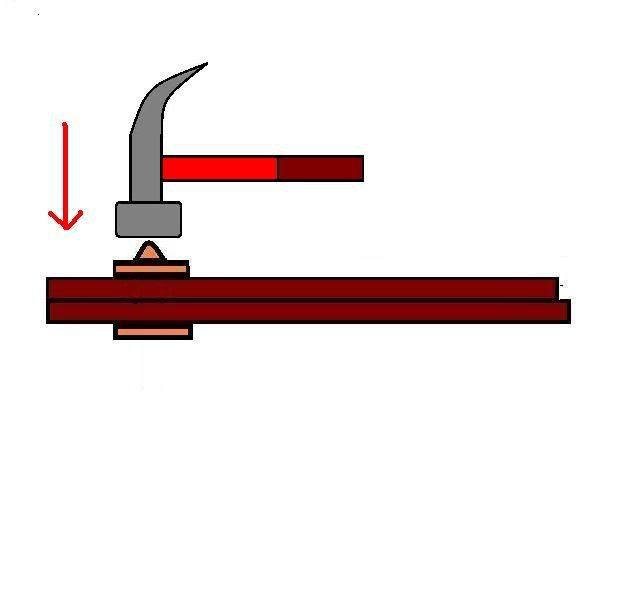

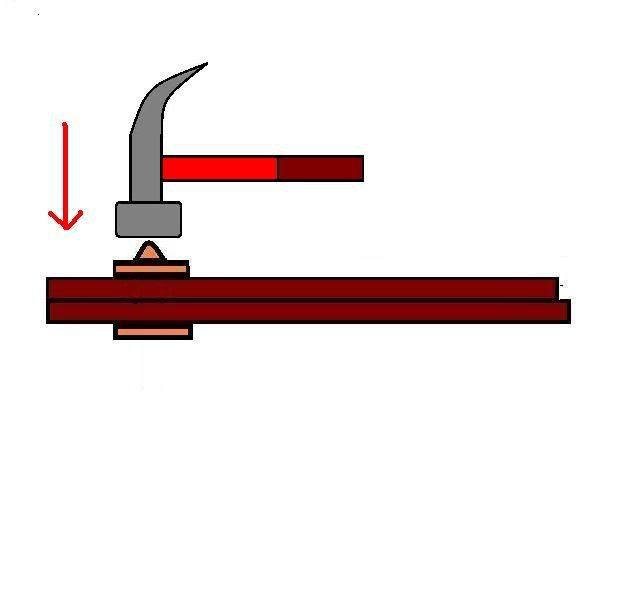

3. tap once or twice with soft wooden hammer like this one

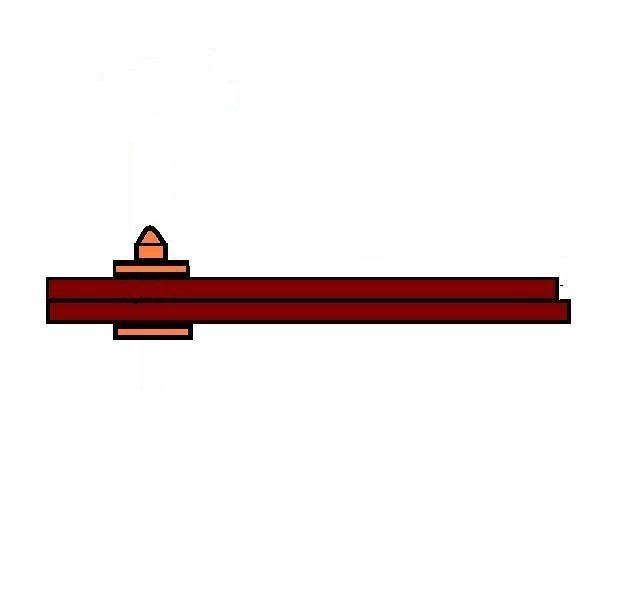

And viola, done! Quick and easy as they are called, just do not expect them to withstand much stress!

To rivet the copper shank rivets is a more complicated process, requiring a few more tools and patience, but the reward is strength and support in the piece.

1. Tools needed-

-of course, copper rivets and washer burs

-Solid steel hammer, a standard cheap clawhammer works fine

-bolt snips,available at any hardware store. I bought mine at Home Depot for $7.

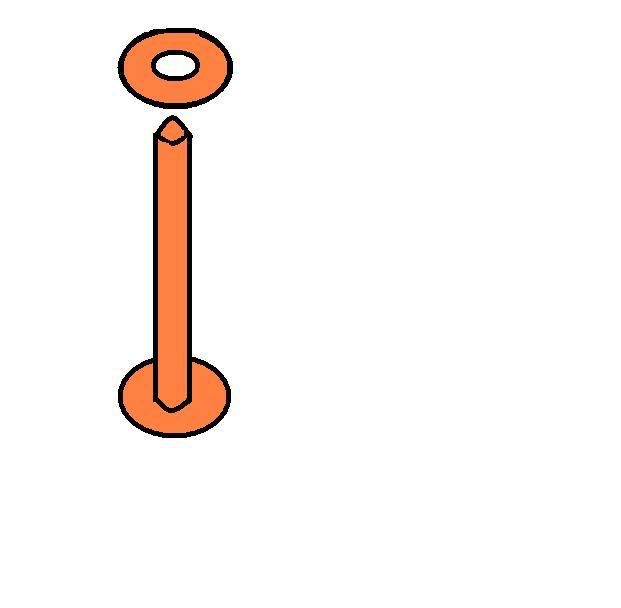

- rivet setter, a more speciality tool, usually only avaiable at Leather working stores, with 2 holes, one long tunnel for pushing washers down the shank, and one bowlish pit for rounding of the sharp tip of the rivet. I got mine at Tandyleatherfactory for about $5

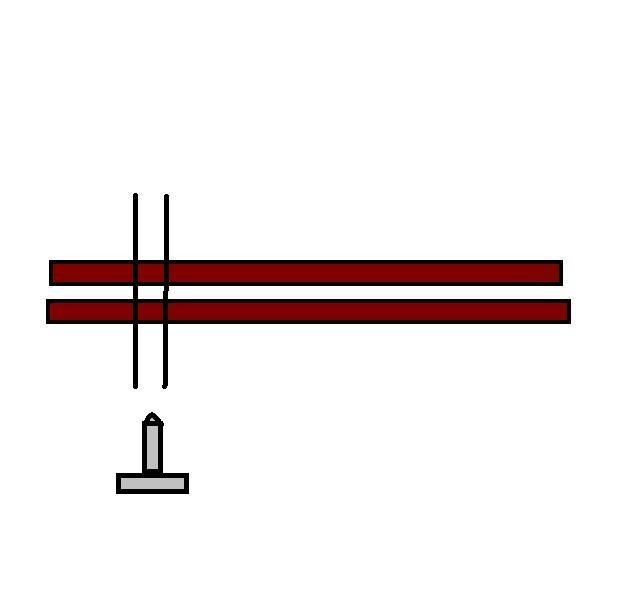

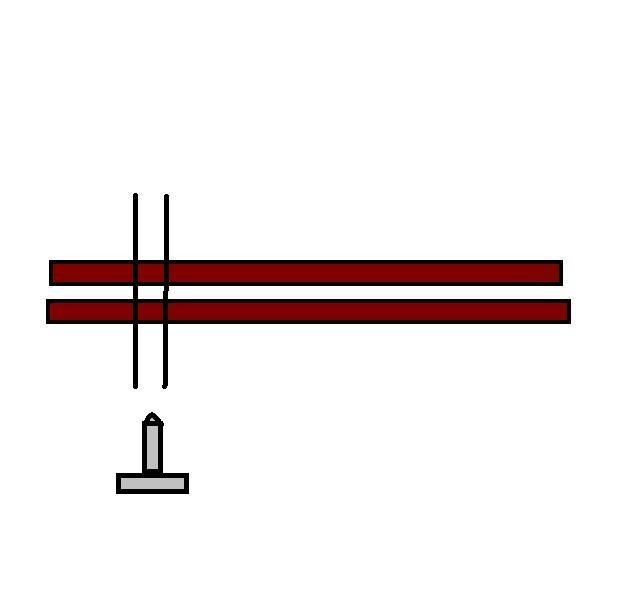

2. Drill holes in leather of course, making sure they match up and are ready to be attached:

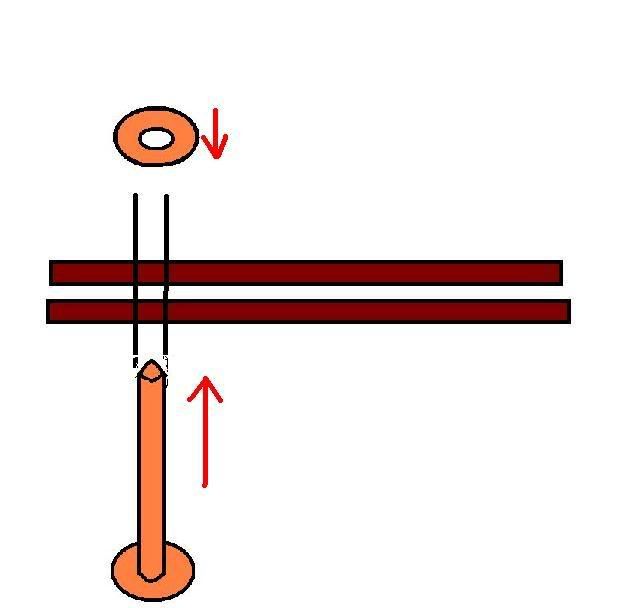

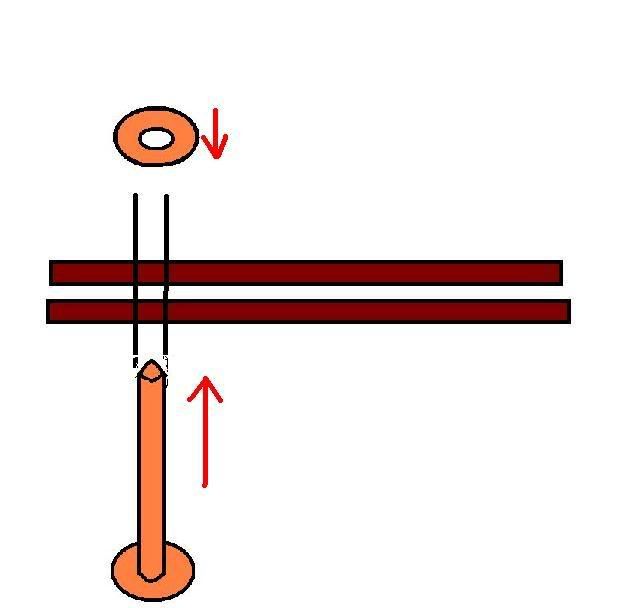

3. Feed the rivet through the bottom layer of layer, matching up through holes and fed completley through:

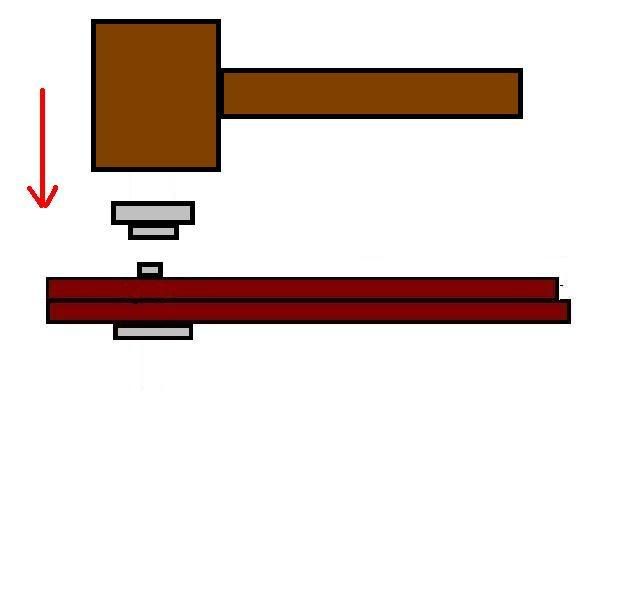

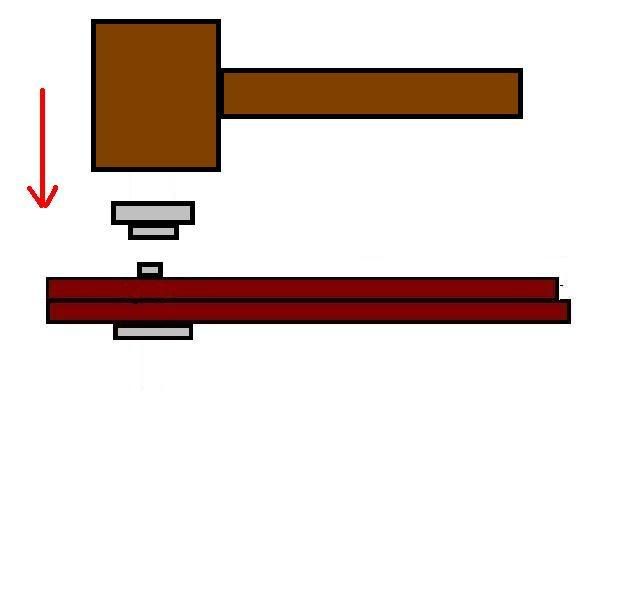

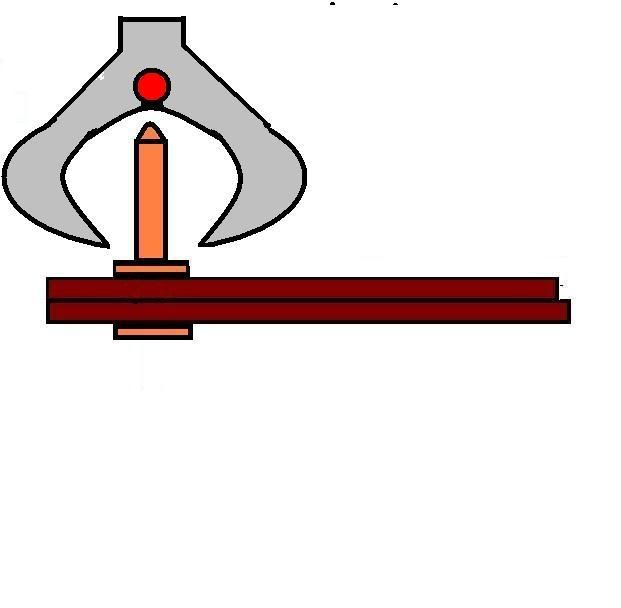

4. Place the bur on the tip of the rivet shank and with the hammer strike the washer down over the shank through the tunnel hole on the setter:

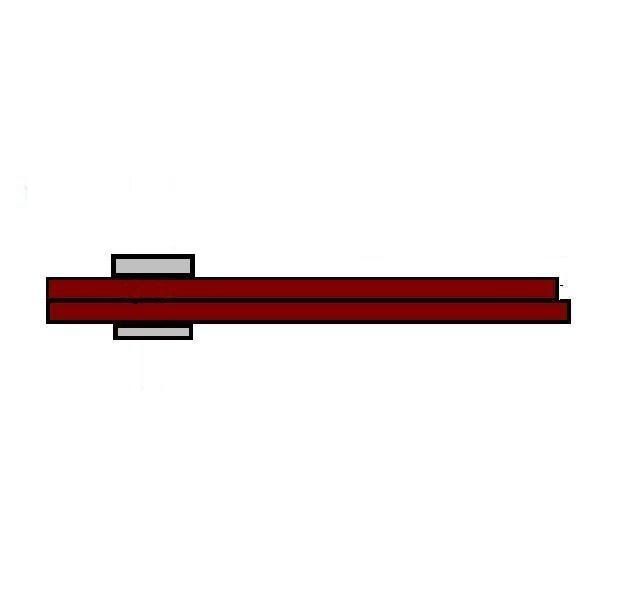

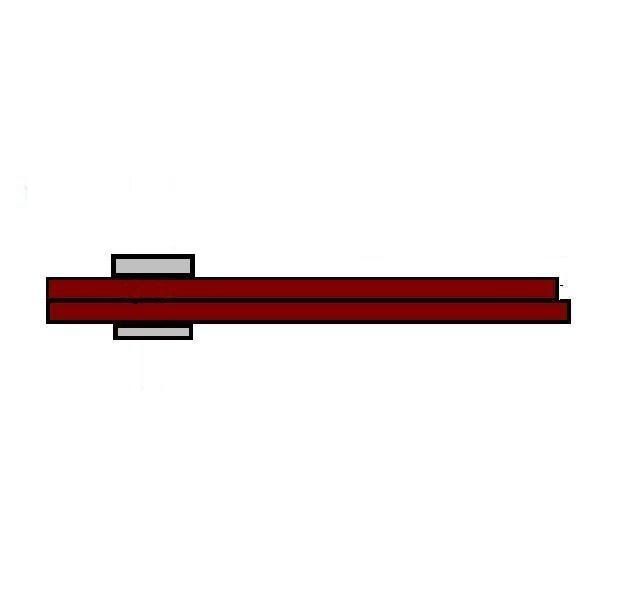

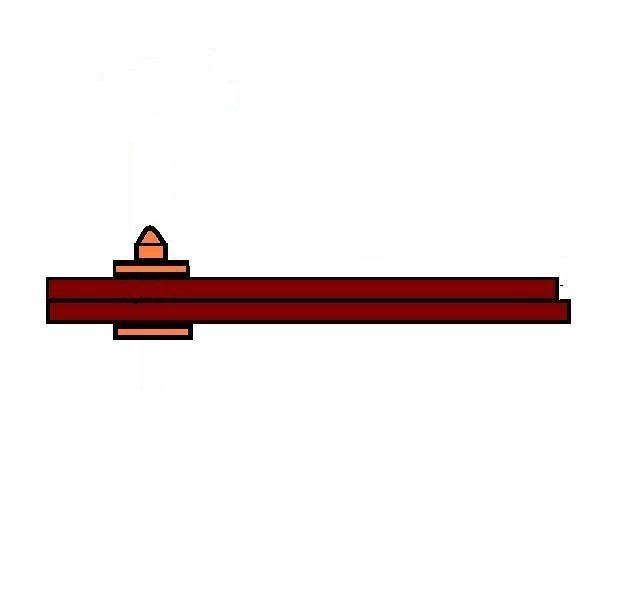

5. Use your bolt snips to cut off the most available neck of the rivet sticking from the surface of the leather:

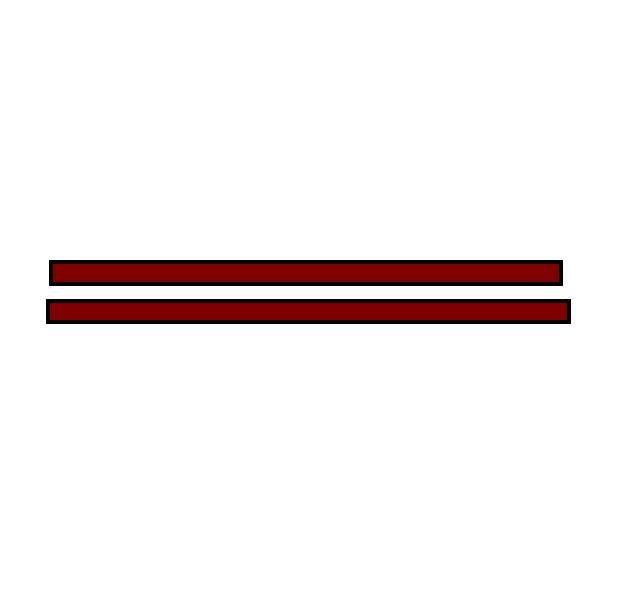

6. Use the small round dimple hole on the setter to round off the tip of the rivet which was sharpened by the bolt cutting:

7. Use the flat of your clawhammer to strike once or twice lightly on the domed rivet tip to round of finished rivet:

And viola, copper rivet complete with strength and safety rounded tip.

Rivetting is an essential task in most leather pieces, although not all, and can really help in the develoupment of your individual unique piece.

Good luck with all your projects and remember patience pays in the end with a work of art you will be proud of!

solid copper rivets with washers called burs:

and hollow lightweight quich rivets, made mostly from thin steel, and colored brass, blackened, or nickel silver:

The quick rivets are used predominately in areas not directly in contact with combat,ie: fashion pieces or occasional strapping. For areas with heavy stress is implied, like areas struck in combat, the solid copper rivets are recommended for their strength.

To attach the quick rivets is very easy and fast, albeit not very strong for the piece. Steps are

1. Feed the long neck end through the bottom of your two pieces of leather.

2. Cover long neck end with cap

3. tap once or twice with soft wooden hammer like this one

And viola, done! Quick and easy as they are called, just do not expect them to withstand much stress!

To rivet the copper shank rivets is a more complicated process, requiring a few more tools and patience, but the reward is strength and support in the piece.

1. Tools needed-

-of course, copper rivets and washer burs

-Solid steel hammer, a standard cheap clawhammer works fine

-bolt snips,available at any hardware store. I bought mine at Home Depot for $7.

- rivet setter, a more speciality tool, usually only avaiable at Leather working stores, with 2 holes, one long tunnel for pushing washers down the shank, and one bowlish pit for rounding of the sharp tip of the rivet. I got mine at Tandyleatherfactory for about $5

2. Drill holes in leather of course, making sure they match up and are ready to be attached:

3. Feed the rivet through the bottom layer of layer, matching up through holes and fed completley through:

4. Place the bur on the tip of the rivet shank and with the hammer strike the washer down over the shank through the tunnel hole on the setter:

5. Use your bolt snips to cut off the most available neck of the rivet sticking from the surface of the leather:

6. Use the small round dimple hole on the setter to round off the tip of the rivet which was sharpened by the bolt cutting:

7. Use the flat of your clawhammer to strike once or twice lightly on the domed rivet tip to round of finished rivet:

And viola, copper rivet complete with strength and safety rounded tip.

Rivetting is an essential task in most leather pieces, although not all, and can really help in the develoupment of your individual unique piece.

Good luck with all your projects and remember patience pays in the end with a work of art you will be proud of!